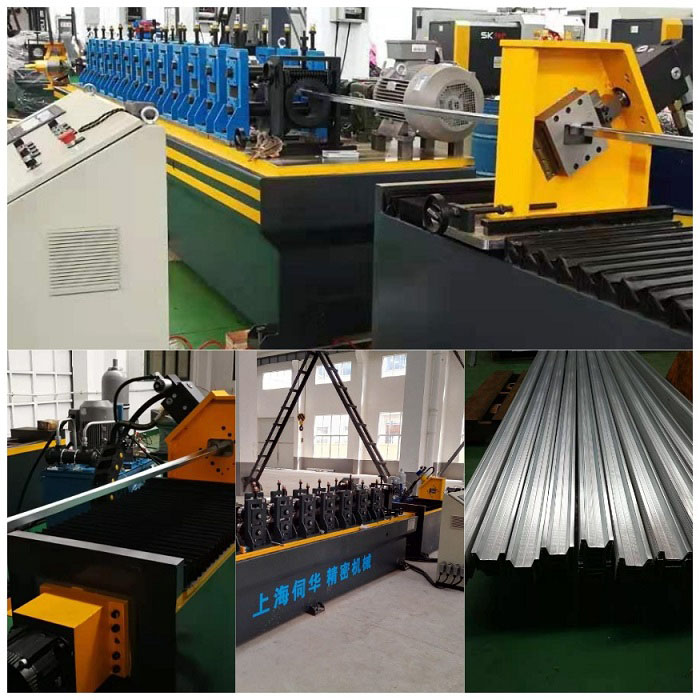

Ulayini wokukhiqiza we-chassis wezimoto zokuqinisa izimoto zezimoto B

I-uncoiler emithathu kweyodwa ezenzakalelayo ngokuphelele ekuqaleni isebenzisa isilawuli sokuqina kwe-servo ukuze kuqinisekiswe ukudla okuzinzile, kuyilapho i-level enembayo engu-16 iqeda ukucindezelwa kwezinto ezibonakalayo. Ngaphezu kwalokho, isistimu yokulinganisa i-laser iqinisekisa ukucaba kweshidi ekubekezeleni okungu-≤0.1mm, ibeka isisekelo sokwakheka okulandelayo.

Ifakwe umshini wokunyathelisa we-punch omkhulu wamathani angu-600 kanye nokushaya ngokunemba kuyafa, ifinyelela ukunemba okuphezulu kakhulu okungu-±0.1mm emigodini yokufaka ye-anti-collision beam, isusa isidingo sokucutshungulwa kwesibili.

I-Precision punching die isho ithuluzi elinemba okuphezulu elisetshenziswa ezinqubweni zokugxiviza zensimbi ukubethela, okungenalutho, noma ukubhoboza izinto ezinokubekezelela okuqinile kanye nokuqedwa kahle kwendawo.

Izici Eziyinhloko:

1.Ukunemba Okuphezulu - Igcina ukubekezelelana okuqinile (ngokuvamile ngaphakathi ± 0.01mm noma okungcono).

Ikhwalithi ye-2.Fine Edge - Ikhiqiza ukusikeka okuhlanzekile ngama-burrs amancane.

3.Ukuqina - Kwenziwe ngensimbi yamathuluzi eqinile (isb, SKD11, DC53) noma i-carbide impilo ende yesevisi.

4.Izimo Eziyinkimbinkimbi - Ezikwazi ukubhoboza amajiyometri ayinkimbinkimbi ngokuphindaphinda okuphezulu.

I-5.Optimized Clearance - I-punch-die clearance efanele iqinisekisa ukuhlukaniswa kwezinto ezibushelelezi.

Inqubo yokugingqika eqhubekayo yamaphasi angu-50, elungiselelwe isofthiwe ye-German Copra, iqinisekisa ukuwohloka okufanayo kwensimbi ngesikhathi sokugoba okubandayo. Isistimu yokuqapha ukucindezeleka kwesikhathi sangempela, esebenza ngokubambisana ne-servo drive, igcina ukubekezelelana kwe-dimensional ± 0.3mm esigabeni esimise okwe-B. Ukuguqulwa kwe-arc okunembile kuma-engeli angakwesokudla kuvimbela ukugxila kwengcindezi.

Roller impahla:CR12MOV (skd11/D2) vacuum ukushisa ukushisa 60-62HRC

Ulayini wokukhiqiza ufakwe imishini emibili yokushisela laser ye-TRUMPF ekuxhumaneni kwemishini emibili. Isibhamu esiyinhloko se-welding sinesibopho se-welding yokungena ejulile ukuze kuqinisekiswe amandla, kuyilapho ikhanda le-welding eli-oscillating liphatha amalunga ekhoneni. Ngaphezu kwalokho, isistimu yokuhlola okubonwayo eku-inthanethi ithola amaphutha e-weld ngesikhathi sangempela, iqinisekisa ukuthi amandla okushisela afinyelela okungenani ku-85% wezinto eziyisisekelo.

Isilawuli sethu se-shear singenisa sisuka e-Italy

Ukunquma indawo enembayo ephezulu

Ukubekezelela Ubude bephrofayili eqediwe ngu-1mm ngamapice ngamunye